Environmental initiatives

We are working to reduce environmental loads by checking energy consumption.

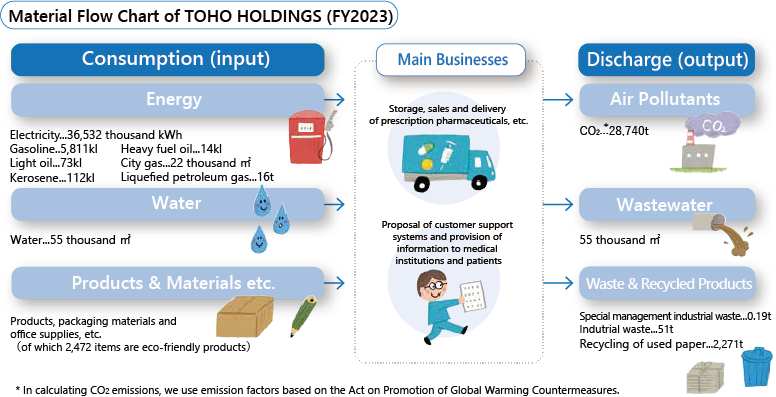

Through our business activities, we use energy, water resources, products, and materials (inputs), and as a result, we discharge CO2, wastewater, and waste (outputs). We monitor material flows continuously to promote environmental load reduction effectively.

Target Organization of Material flow: TOHO HOLDINGS, TOHO PHARMACEUTICAL, SAYWELL, KOYO, Kyushu Toho, TOHO SYSTEMS SERVICE,

We use BEMS to manage energy consumption at logistics centers.

The Company's mission is to provide a stable supply of pharmaceuticals. To ensure safe and secure delivery of pharmaceuticals at any time, we have established distribution centers throughout Japan. Distribution centers have many air conditioners and a lot of lighting equipment and use large material handling equipment and robots. This results in higher electricity consumption than other business offices. For this reason, we have introduced BEMS at our distribution centers to manage the consumption.

In addition, robots at TBC DynaBASE are operated also by utilizing night-time electricity, and the head part, where the robot vacuums products, is a power-saving type that stops vacuuming when a certain amount of power is generated. The automatic warehouse is a regenerative energy type that is charged when the conveyor brakes. The system is also used at TBC Hiroshima and TBC Saitama.

Switching to Renewable Energy Plans

Since December 2023, the Group has been gradually switching from fossil fuel electricity to renewable energy. Going forward, we will continue to introduce this system, mainly at distribution centers, which use large amounts of electricity.

We are switching from gasoline-powered vehicles to EVs.

We are preventing disposal losses on pharmaceuticals.

If a manufacturing and sales business operator violates GMP (Good Manufacturing Practices), it must recall and dispose of the drug in question. At KYOSOMIRAI PHARMA CO., LTD., which engages in the manufacturing and sales of prescription pharmaceuticals, its major proposition is compliance with Good Manufacturing Practice (GMP). On this basis, we forecast market demand in cooperation with the Group's wholesale and dispensing pharmacy businesses so as not to generate waste products caused by excess production.

We have acquired ISO 14001 certification and are making continuous improvements.

Plant at KYOSOMIRAI PHARMA has acquired ISO 14001:2015 certification, an international standard for environmental management systems, in order to continuously improve activities of energy conservation and waste reduction.

Participating in a medical devices recycling project

We are contributing to the reduction of plastic waste by participating in "ReMedTM," Japan's first recycling project for used pen-type injectors. We are contributing to the reduction of plastic waste by participating in "ReMedTM," a new mission for used medical devices.